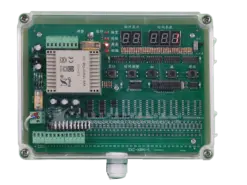

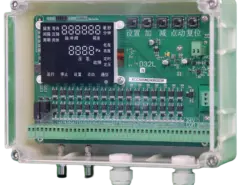

The offline cleaning X8B2 pulse controller panel is equipped with a dot matrix LCD screen, which can sequentially display the working sequence of the pulse valve. The number of lifting valves, pulse valves, interval time, pulse width, pulse interval, and cycle interval can be adjusted according to the cleaning needs. The opening and closing of the solenoid valve can be controlled, and the dust collector can be cleaned regularly. At the same time, there is an input node for a differential pressure controller. After connecting the differential pressure controller and differential pressure transmitter, the differential pressure can be set for dust cleaning. There are corresponding communication interfaces for PLC and DCS.

Model specification table:

| Number of valve controlled | Type | Shell material | External dimensions (mm)

H×W×L |

| 1-40 | Single machine/networked | Cast-aluminum shell | 250×185×88 |

Product parameters:

| Input voltage | AC220V(±10%)50HZ/60HZ |

| Output voltage | DC24V |

| Output current | 3.5A |

| Power | 84W |

| Lift valve adjustment range | 0-99 |

| Waiting time adjustment range | 0.001s-99999.999s ,accuracy:1ms |

| Settlement time adjustment range | 0.001s-99999.999s,accuracy:1ms |

| Adjustment range of interval time | 0.001s-99999.999s,accuracy:1ms |

| Pulse valve adjustment range | 0-9999 |

| Pulse width time adjustment range | 0.001s-99999.999s,accuracy:1ms |

| Interval time adjustment range | 0.001s-99999.999s,accuracy:1ms |

| Cycle time adjustment range | 0.001s-99999.999s,accuracy:1ms |

| Start delay adjustment range | 0.001s-99999.999s,accuracy:1ms |

| Control model | 1-Timing 2-Delta P |

| Usage environment | Working temperature -20 ℃~+60 ℃; The relative humidity of the air shall not exceed 85%; (No ice or frost)

No severe corrosive gases and conductive dust; No severe vibration or impact |