High-Efficiency Semicoke Dust Collector Systems with Superior Thermal Stability

| Model Number | Filter Area (m²) | Bag Quantity (pcs) | Pulse Valve (pcs) | Air Volume (m³/h) | Dimensions (L×W×H mm) | Weight (kg) |

| MC24-2 | 18 | 24 | 4 | 2,160 – 4,300 | 1025×1678×3700 | 830 |

| MC36-2 | 27 | 36 | 6 | 3,250 – 6,480 | 1425×1678×3696 | 1106 |

| MC48-2 | 36 | 48 | 8 | 4,320 – 8,630 | 1823×1678×3676 | 1224 |

| MC60-2 | 45 | 60 | 10 | 5,400 – 10,800 | 2225×1678×3676 | 1341 |

| MC72-2 | 54 | 72 | 12 | 6,450 – 12,900 | 2625×1678×3676 | 1564 |

| MC84-2 | 63 | 84 | 14 | 7,550 – 15,100 | 3075×1678×3676 | 2012 |

| MC96-2 | 72 | 96 | 16 | 8,650 – 17,300 | 3949×1678×3676 | 2130 |

| MC120-2 | 90 | 120 | 20 | 10,800 – 20,800 | 4389×1678×3676 | 2410 |

| Item | Specification | Remarks |

| Brand | Xiechang | China Top Brand |

| Origin | Suzhou, China | Direct Factory Supply |

| Controller | JMK-2 Type Pulse Instrument | High-Precision Timing |

| Filter Bag Size | ¢125 × 2050 mm | Customizable Materials |

| Efficiency | 99% – 99.99% | Application Dependent |

| Resistance | 120 – 150 mmH₂O | Low Pressure Drop Design |

| Filtration Speed | 2.0 – 4.0 m/min | Optimized Air-to-Cloth Ratio |

| Inlet Dust Content | 3 – 15 g/m³ | High Concentration Ready |

| Working Pressure | 4.0 kg/cm² | Stable Pulse Cleaning |

High-Performance Air Filtration Solutions by Xiechang (Suzhou)

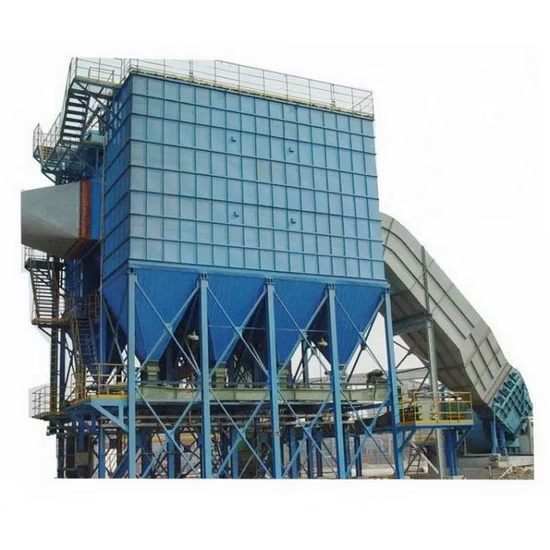

The Xiechang brand MC series pulse jet baghouse is a high-efficiency dust collection system specifically engineered for the Semicoke industry and other challenging industrial environments. Manufactured in Suzhou, China’s premier industrial filtration hub, our systems integrate advanced domestic and international technologies with multiple Xiechang patents in compressed air blowing and airflow distribution.

Why Choose Xiechang Semicoke Dust Collectors?

-

Ultra-High Efficiency: Achieves a filtration rate of over 99.99%, capturing even the finest solid particulates.

-

Superior Temperature Resistance: Capable of continuous operation in conditions exceeding 200ºC when equipped with premium materials like PTFE, P84, or Glass Fiber.

-

Patented Innovation: Optimized compressed air systems ensure low steel consumption, minimal structural resistance, and a compact footprint.

-

Suzhou Quality Assurance: Precision-engineered in our Suzhou facility to meet rigorous global industrial standards.

System Structure & Operational Principle

Component Breakdown

-

Upper Box: Includes the reinforced cover plate and clean air outlet.

-

Middle Box: The core filtration zone featuring perforated plates, filter frames (cages), bags, and venturi tubes.

-

Under Box: Includes the heavy-duty ash hopper, air intake manifold, and quick-access doors.

-

Jetting System: Powered by Xiechang patented pulse valves, electromagnetic solenoids, injection piping, and air headers.

Working Principle

Dust-laden gas enters the middle and lower boxes; particulates are trapped on the outer surface of the filter bags while clean gas exits through the venturi and upper box. As the dust layer thickens, the system resistance increases. The Xiechang Intelligent Controller triggers the pulse valves, releasing a high-pressure burst of air through the venturi. This causes an instantaneous expansion of the bag, shaking off the dust into the hopper and recycling the filter media automatically.