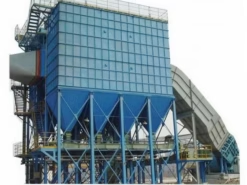

High-Efficiency Pulse Jet Dust Collectors by Xiechang®

Maintain a clean, compliant, and productive workspace with Xiechang’s advanced pulse jet dust collectors (Baghouses). Our systems are engineered in Suzhou to provide industry-leading filtration efficiency (up to 99.99%) for demanding sectors ranging from asphalt mixing and cement production to metallurgy and power generation.

By integrating Xiechang® patented pulse jet technology, our collectors ensure maximum dust recovery with minimal energy consumption. Whether you are handling high-temperature gases or fine abrasive particulates, our custom-engineered baghouses deliver the rugged reliability required for 24/7 continuous operation.

Why Industries Trust Xiechang® Dust Collectors

- Patented Cleaning Logic: Equipped with Xiechang® pulse valves, our systems deliver precise air bursts that extend filter bag life and reduce compressed air waste.

- Thermal Resilience: Optimized for extreme conditions, our high-temp series operates reliably in environments exceeding 200°C using premium PTFE or Nomex media.

- Low Maintenance Design: Featuring easy-access doors and tool-free bag replacement, our collectors minimize downtime and labor costs.

- Eco-Friendly Compliance: Achieve outlet emissions as low as <10mg/Nm³, meeting the strictest global environmental regulations.

Technical FAQs: Pulse Jet Dust Collectors

Q: What is the ideal Air-to-Cloth (A/C) ratio for an asphalt plant dust collector?

The A/C ratio (filtration velocity) typically ranges from 0.8 to 1.2 m/min for asphalt mixing applications. A lower ratio ensures better filtration and longer bag life when handling the high-moisture and oily dust common in asphalt production. Xiechang® engineers can calculate the exact ratio needed based on your plant’s TPH (Tons Per Hour) capacity.

Q: How does Xiechang’s patented pulse system improve baghouse performance?

Traditional systems often suffer from uneven air distribution. Xiechang’s optimized blowing system uses patented airflow distribution plates and high-response pulse valves to ensure every filter bag—from the first to the last in a row—receives the same cleaning energy. This prevents "dust blinding" and maintains a stable pressure drop across the system.

Q: Can your dust collectors be customized for explosive or corrosive dust?

Yes. Xiechang® provides specialized configurations including explosion-proof (ATEX-compliant) vent panels, anti-static filter bags, and stainless steel housings for corrosive chemical or food-grade applications.

Q: When should I consider upgrading my old baghouse to a Xiechang® pulse jet system?

If you are experiencing high compressed air costs or failing to meet new emission standards, it is time for an upgrade. Retrofitting your existing collector with Xiechang® pulse valves and controllers often pays for itself within 18–24 months through energy savings.