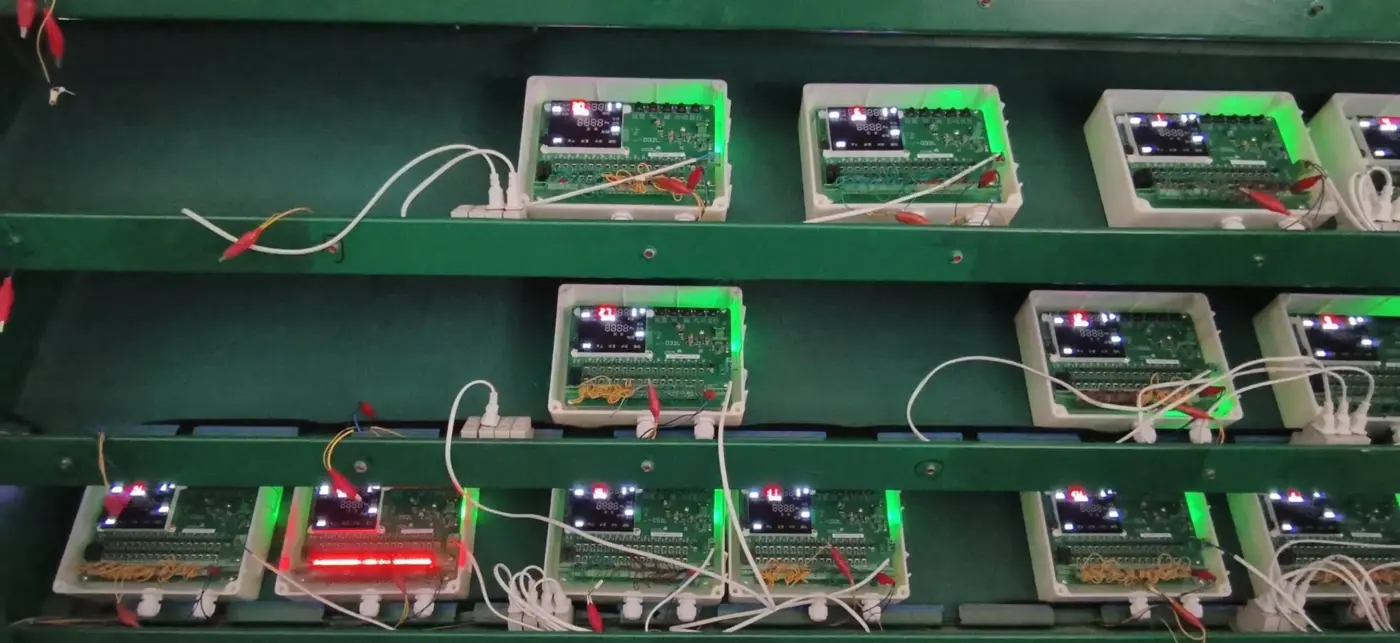

Intelligent Pulse Jet Control Systems by Xiechang®

Take full command of your dust collection efficiency with Xiechang® Pulse Jet Controllers. As the "brain" of your baghouse, our controllers are engineered to provide precise timing and sequencing for pulse valve actuation. By optimizing the cleaning intervals and pulse duration, Xiechang® controllers significantly reduce compressed air consumption while maintaining a stable differential pressure across your filter bags.

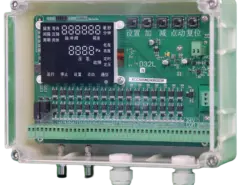

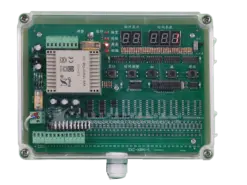

From compact units for small collectors to advanced PLC-integrated systems for large-scale industrial plants, Xiechang® offers a variety of control solutions. Our controllers are built to withstand harsh industrial environments, featuring dust-proof enclosures and high-reliability circuitry that ensures your cleaning system operates without interruption.

Key Features of Xiechang® Pulse Controllers

-

Precision Timing Control: Easily adjustable pulse width (on-time) and pulse interval (off-time) to match your specific dust loading requirements.

-

Dual Operating Modes: Supports both "On-line" and "Off-line" cleaning sequences, providing flexibility for different baghouse designs.

-

Intelligent Differential Pressure Logic: Available models with built-in pressure sensors that trigger cleaning only when needed, saving energy and extending filter bag life.

-

Robust Protection: High-grade enclosures (IP65 rated) protect internal components from dust, moisture, and electrical interference.

-

User-Friendly Interface: Clear digital displays and intuitive programming buttons make setup and monitoring simple for maintenance teams.

Optimized for Seamless Integration

Xiechang® Pulse Controllers are designed to work in perfect harmony with Xiechang® pulse jet valves. This synchronization ensures that the electrical signal and pneumatic response are perfectly aligned, resulting in the most effective dust dislodgement possible. Our systems are the trusted choice for asphalt plants, cement factories, and power plants worldwide.

Technical FAQs: Pulse Jet Controllers

Q: What is the difference between On-line and Off-line cleaning modes? On-line cleaning occurs while the dust collector is still filtering air, whereas Off-line cleaning shuts down a specific compartment before pulsing. Xiechang® controllers can be configured for both. Off-line cleaning is often more effective for very fine or lightweight dust, as it prevents "re-entrainment" where dust simply moves from one bag to another.

Q: How can a pulse controller help reduce my factory's energy costs? By using a Xiechang® demand-mode controller (based on differential pressure), the system only fires the valves when the bags are actually dirty. This reduces the frequency of pulsing, which saves a massive amount of compressed air—often the most expensive utility in a plant—and reduces wear and tear on the valve diaphragms.

Q: Can Xiechang® controllers be integrated into our factory’s main PLC system? Yes. Many of our advanced models feature remote start/stop capabilities and output signals (such as 4-20mA or RS485 Modbus) that allow your central control room to monitor the baghouse status and pressure drop in real-time.

Q: How many valves can a single Xiechang® controller handle? We offer a wide range of models, from 10-point controllers for small units to expandable systems capable of controlling 100+ valves. You can choose the output channels that best fit your manifold configuration.