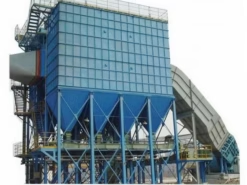

XC-Series High-Capacity Industrial Cartridge Dust Collector with Multi-Stage Filtration

Product Description

The XC-Series Industrial Cartridge Dust Collector is a heavy-duty, central purification system engineered for large-scale industrial manufacturing environments. This high-capacity unit features a modular design with an extensive array of high-precision filter cartridges, designed to handle massive volumes of airborne particulate matter.

Built for durability and continuous operation, the system utilizes a sophisticated downward flow design and an automated pulse-jet cleaning mechanism to maintain optimal suction power. The elevated structure, integrated access platform, and dual hopper discharge system make it the ideal solution for factories requiring centralized, reliable, and low-maintenance air filtration.

Technical Key Points

-

Modular High-Surface Filtration: Equipped with a multi-cartridge array (24+ units) to provide an exceptionally large filtration area for high-volume air processing.

-

Automated Pulse-Jet Cleaning: Integrated pulse valves deliver high-pressure air bursts to clear filters automatically, ensuring constant airflow and reduced manual intervention.

-

Heavy-Duty Structural Design: Features a reinforced steel chassis with an integrated safety mezzanine, handrails, and access stairs for easy maintenance.

-

Dual-Hopper Discharge: Designed with two large-capacity collection hoppers and rotary discharge valves for efficient waste management.

-

Advanced Air Distribution: Downward airflow pattern assists in the natural settling of dust into the hoppers, extending the life of filter media.

-

Industrial Grade Finish: High-durability powder coating protects the structure against corrosion in harsh industrial climates.

Product Benefits

-

Maximum Operational Uptime: The self-cleaning pulse technology allows the system to operate 24/7 without stopping for filter maintenance.

-

Enhanced Workshop Safety: Removes hazardous airborne dust and fine particles, ensuring compliance with environmental and workplace health regulations.

-

Lower Energy Costs: Optimized airflow dynamics reduce the load on the main fan, leading to lower power consumption compared to traditional systems.

-

Ease of Maintenance: The elevated platform and stairs provide safe, direct access for rapid filter inspections and replacements.

-

Scalable Solution: Modular design allows for the integration of additional units to meet growing production demands.

Application Scenarios

-

Metalworking & Fabrication: Ideal for large-scale grinding, sandblasting, and thermal spraying workshops.

-

Chemical & Pharmaceutical: Captures fine powders and chemical particulates in bulk processing facilities.

-

Woodworking & Furniture: Centralized collection for large-scale CNC cutting, sanding, and milling lines.

-

Cement & Mining: Effective for managing high-density dust in material handling and packaging plants.

-

Automotive Manufacturing: Specifically designed for large-scale welding smoke and plasma cutting fume extraction.

Technical Specifications

| Feature | Specification |

| System Type | Centralized Cartridge Dust Collector |

| Filter Quantity | Multi-row Array (Configurable) |

| Cleaning Method | Automatic High-Pressure Pulse-Jet |

| Structure Material | Reinforced Carbon Steel |

| Access Features | Integrated Mezzanine with Safety Stairs |

| Discharge System | Dual Hoppers with Rotary Valves |

| Application Type | Heavy Industrial / Large Scale |