Watson Introduction:

Watson Company was founded in 1983 and began a joint venture with West Germany’s GVD company to design and produce defogger equipment in North America. In 1986, Watson Company acquired and accepted all the shares and technologies of GVD in the North American market. Since then, Watson Company has developed and researched the technology of bag filters and related accessories. It is now a professional company in the North American market that can provide the most complete bag filter and dust removal technology. All the pulse valves provided are high-quality products.

The quality of the pulse valve directly affects the cleaning effect of the bag filter. Poor cleaning will result in high resistance of the bag filter, greatly reducing the lifespan of the bag, and easily causing bag breakage, leading to substandard emissions. Hundreds of pulse valves are hundreds of fault points in large bag filters, and the damage of individual pulse valves can affect the entire cleaning effect. Therefore, the quality of pulse valves is very important.

Suzhou Xiechang Environmental Protection Technology Co., Ltd. is the general agent of Watson Company in the Asia Pacific region, providing technical support and product quality tracking to customers, ensuring the optimal operation of their production equipment. As Watson’s agent in China, Suzhou Xiecheng Environmental Protection Technology Co., Ltd., has a large amount of stock available for a long time, timely meeting the production needs of customers and ensuring their normal production as soon as possible.

Watson Advantage:

- Professional manufacturer;

- Five year quality assurance;

- Comprehensive after-sales service.

Product introduction:

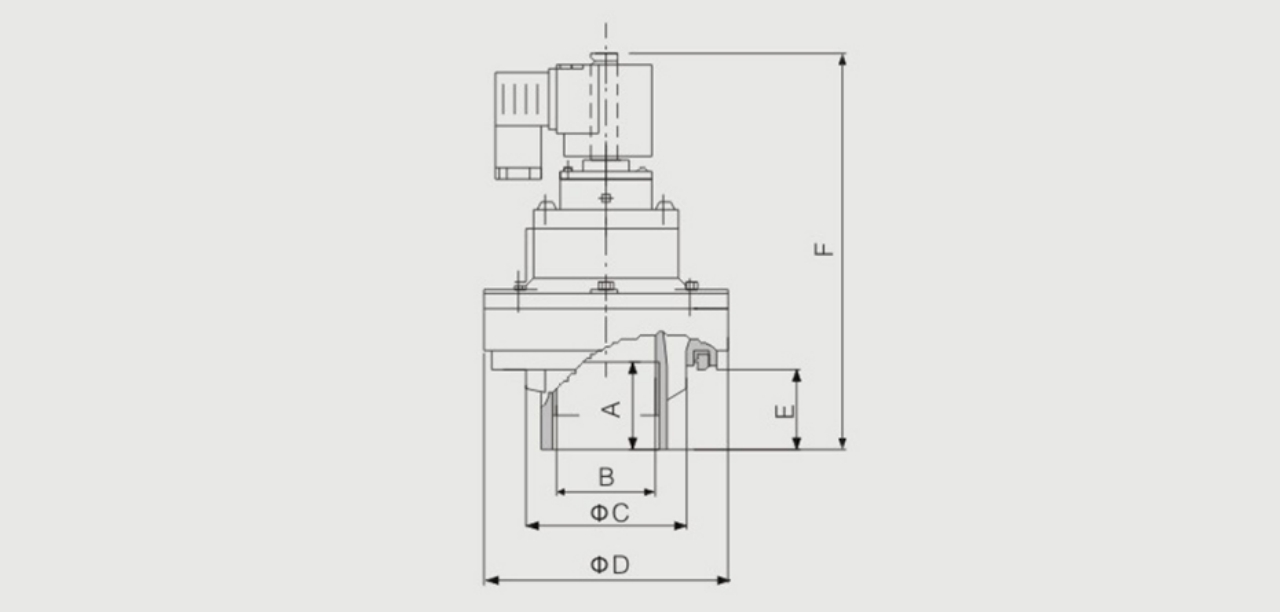

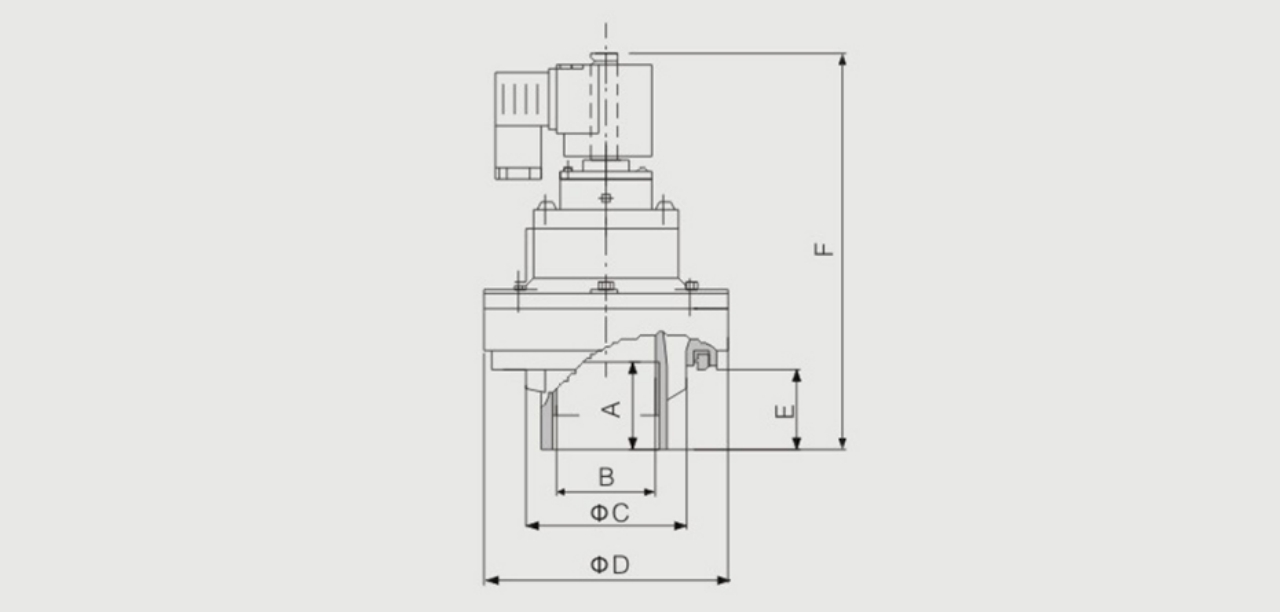

- WPS-CA/EG embedded inner thread type pulse valve installation instructions:

WPS-CA/EG embedded pulse valve, combined with nozzle and air tank, has the characteristics of easy installation and reliable sealing.

1 “~1½” (DN25mm, DN40mm) is a threaded connection between the pulse valve body and nozzle, and the threads should be filled with PTFE raw material tape or thread sealant for fastening and sealing. The air tank and nozzle are tightly connected with compression nuts to form a single piece.

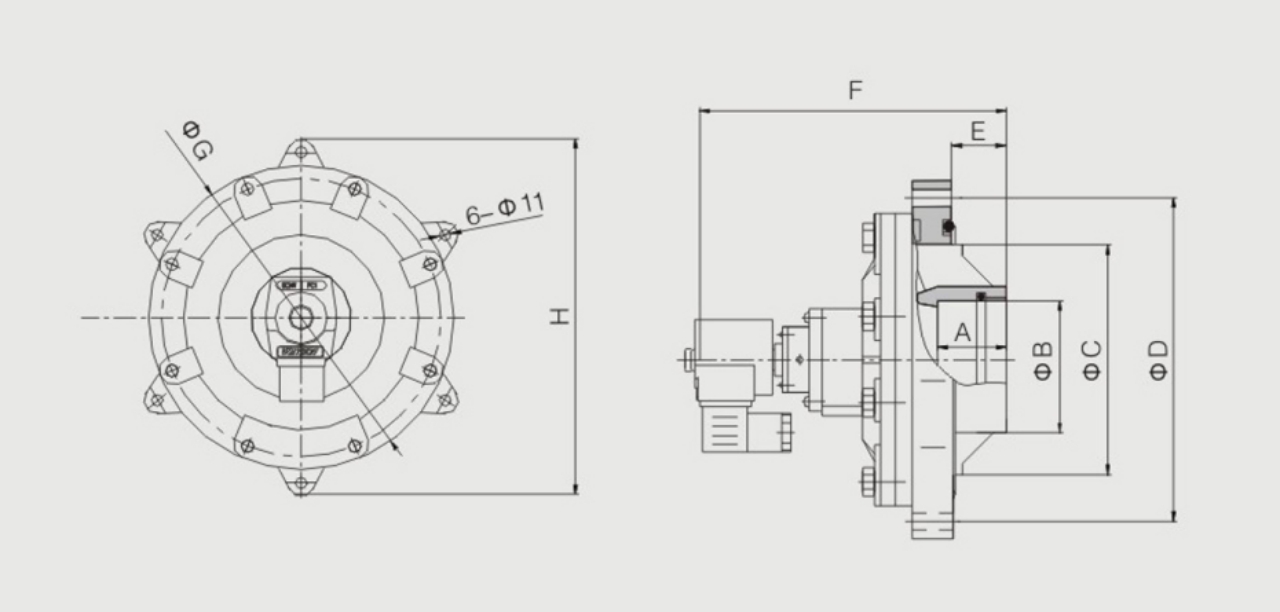

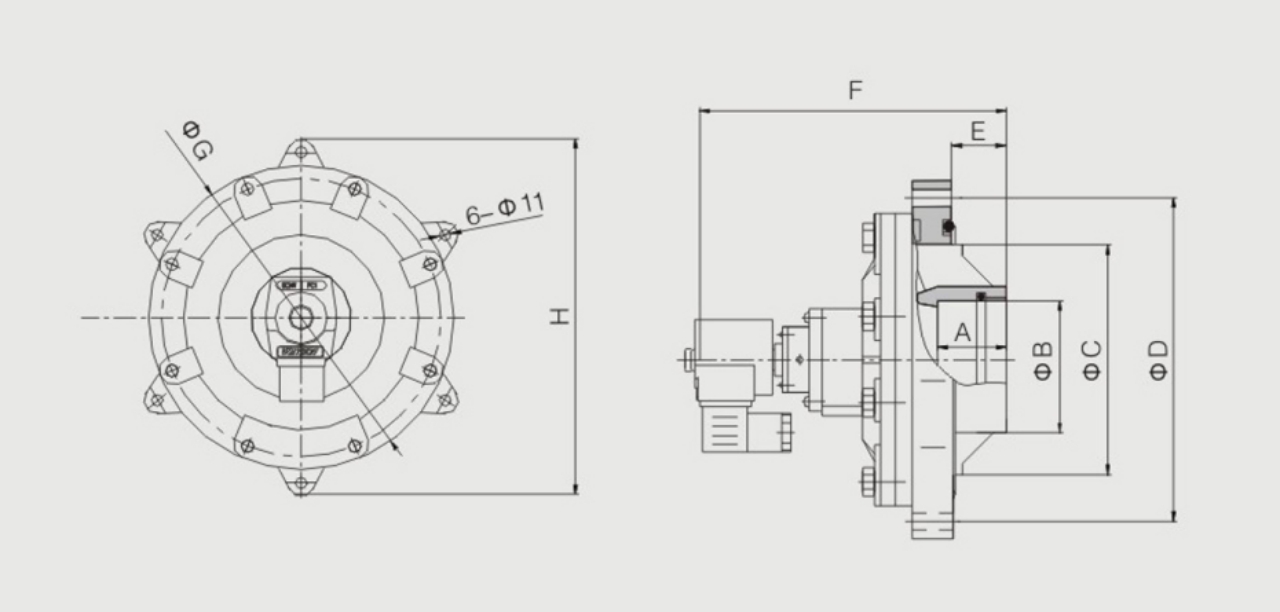

- WPS-CA/EP embedded slide pipe pulse valve installation instructions :

WPS-CA/EP embedded pulse valve combined with nozzle and air tank, with the characteristics of easy disassembly and reliable sealing.

2 “~4” (DN50mm, DN62mm, DN76mm, DN102mm) is a bolted connection between the pulse valve body and the air tank, with a flat sealing ring; The nozzle and valve body are fitted with shaft holes, and the holes are sealed with sealing rings. The nozzle and air tank are tightened and connected together with compression nuts to form a single piece.

Product parameters:

WPS-CA/EG embedded inner thread type pulse valve:

Model No. Valve size A B C D E F WPS-CA/EG25 1″ 40 G1″ 59 96 33 140 WPS-CA/EG40 1 1/2″ 41 G1 1/2″ 73 112 40 182

WPS-CA/EP embedded slide pipe pulse valve:

Model No. Valve size A B C D E F G H WPS-CA/EP50 2″ 41 60.5 122 180 30 188 160 202 WPS-CA/EP62 2 1/2″ 44 75.5 148 208 35 196 188 230 WPS-CA/EP76 3″ 43 89.5 160 227 35 200 200 249 WPS-CA/EP102.B 3.5″ 43 103 170 227 35 207 200 248 WPS-CA/EP102 4″ 40 114 177 227 35 207 219 249 WPS-CA/EP115 4 1/2″ 43 126.5 198 239 35 218 239 261

Technical standard:

Technical category Relevant parameter Working pressure 0.2~0.6MPa Working medium Clean air Voltage DC24V(AC220V/50Hz) Current 1.25A(0.5A) Protection level IP65 Usage environment 1. Room temperature membrane -10 ℃~55 ℃; 2. The relative humidity of the air shall not exceed 85%

Diaphragm service life 1 million times of cycle