1. Product Overview

As global emission standards for the power industry become increasingly stringent, high-efficiency bag filters have become the gold standard for dust removal. The Long-Arm Rotary Tube Nozzle Bag Filter is specifically favored for its ability to handle massive air volumes with low maintenance requirements.

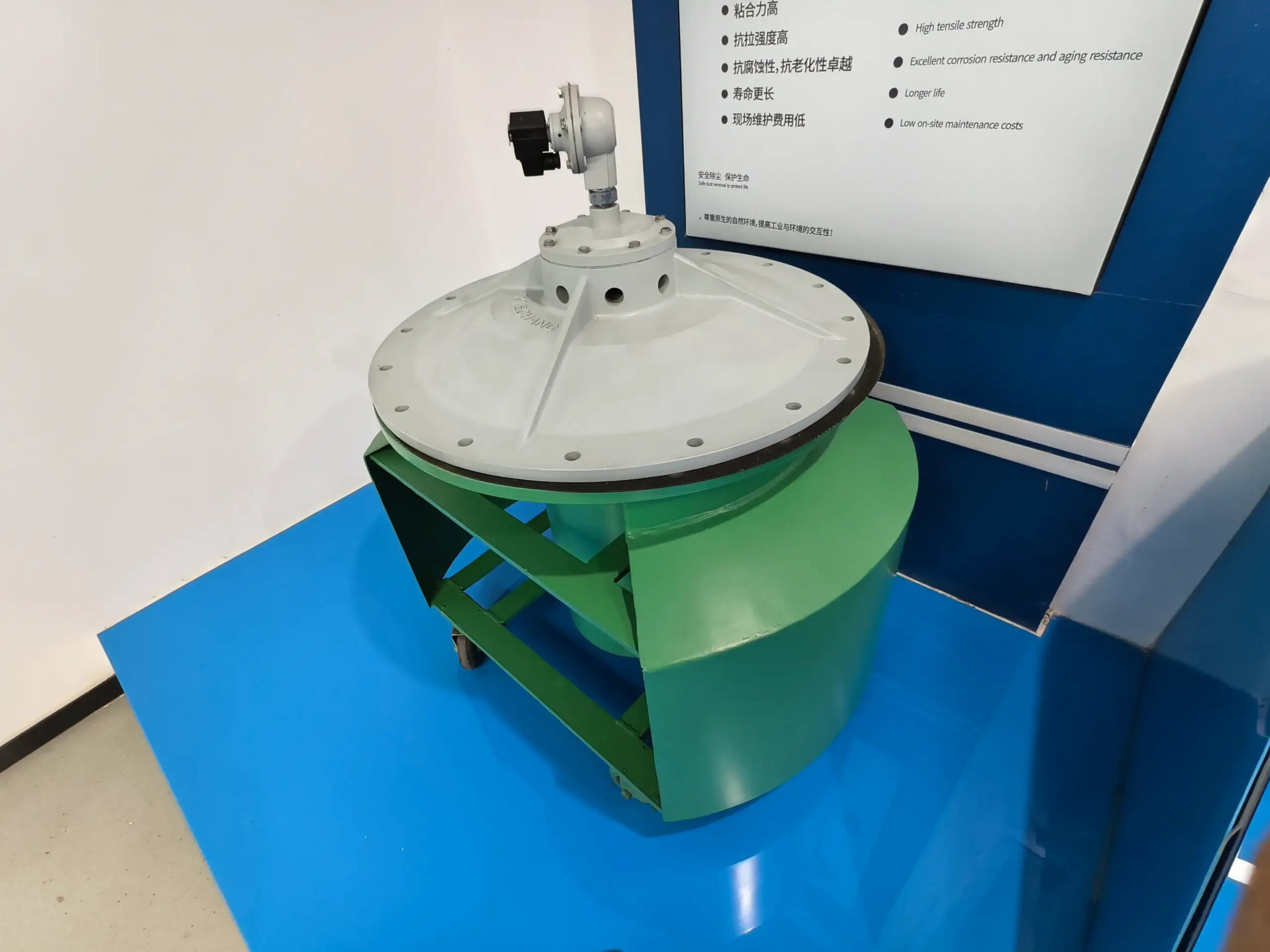

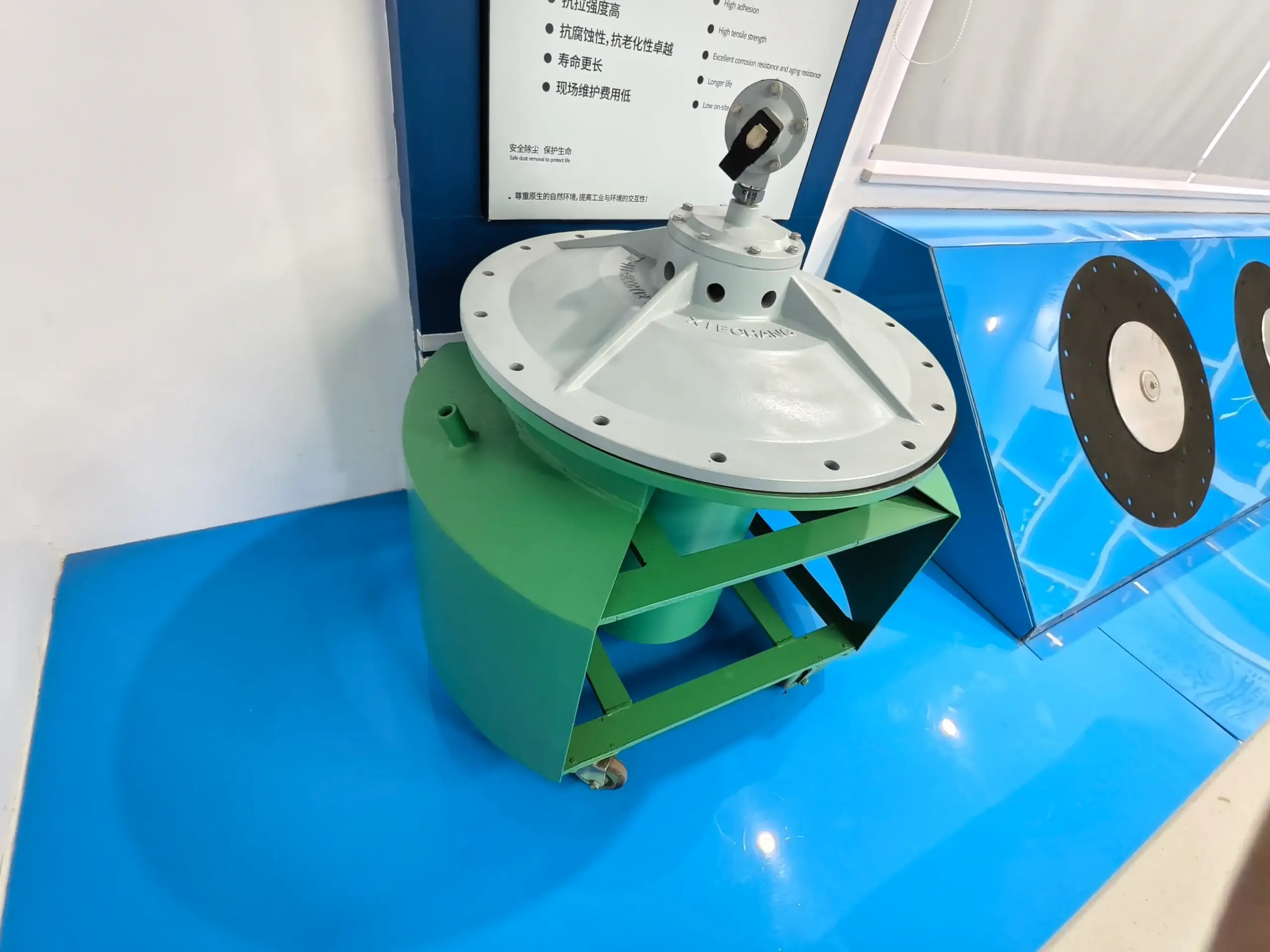

A critical challenge in large-scale systems has been the reliance on imported large-diameter valves, as domestic production was previously limited to valves under 3 inches. To address this gap, our researchers have developed a series of Large-Diameter Pulse Valves available in 8, 10, 12, 14, and 16-inch specifications, designed to meet the high blowing volume demands of modern environmental protection infrastructure.

2. Technical Features & Advantages

-

Three-Stage Diaphragm Technology: Our unique three-stage design optimizes the ratio between unloading, exhaust, and inflation damping, ensuring ultra-high sensitivity and smooth airflow.

-

Extreme Energy Efficiency: Engineered for low-pressure operation (0.05~0.1MPa), these valves significantly reduce the energy consumption of the dust cleaning system.

-

Alternative Air Supply: Due to the low pressure requirements, cost-effective Roots blowers can be used as the gas source instead of expensive high-pressure compressed air systems.

-

Enhanced Power Output: By maximizing the blowing air volume and reducing internal pressure drop, the valve delivers superior cleaning force even at lower pressures.

-

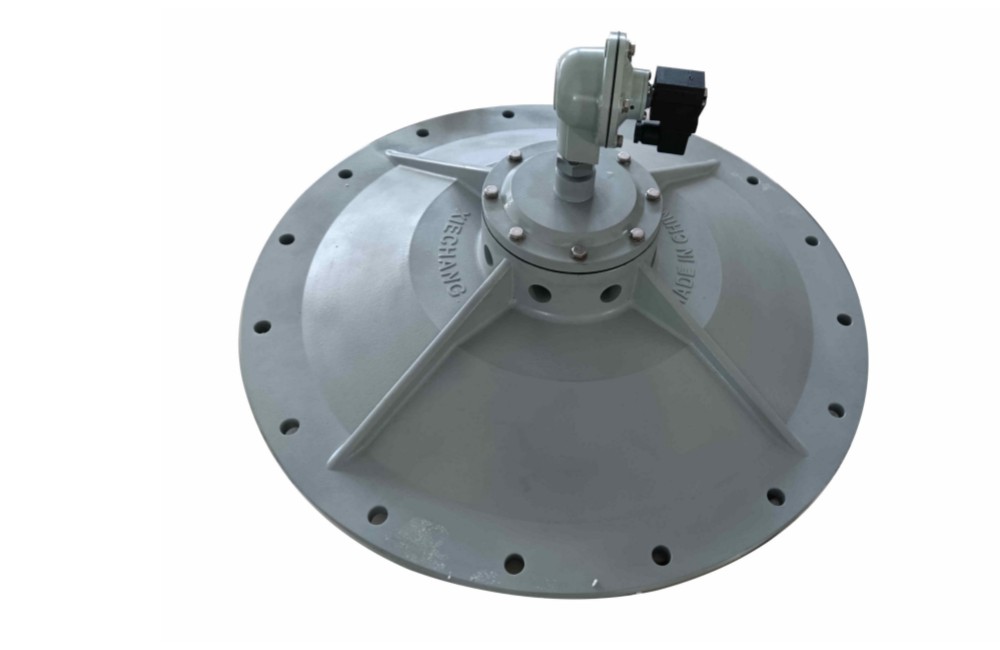

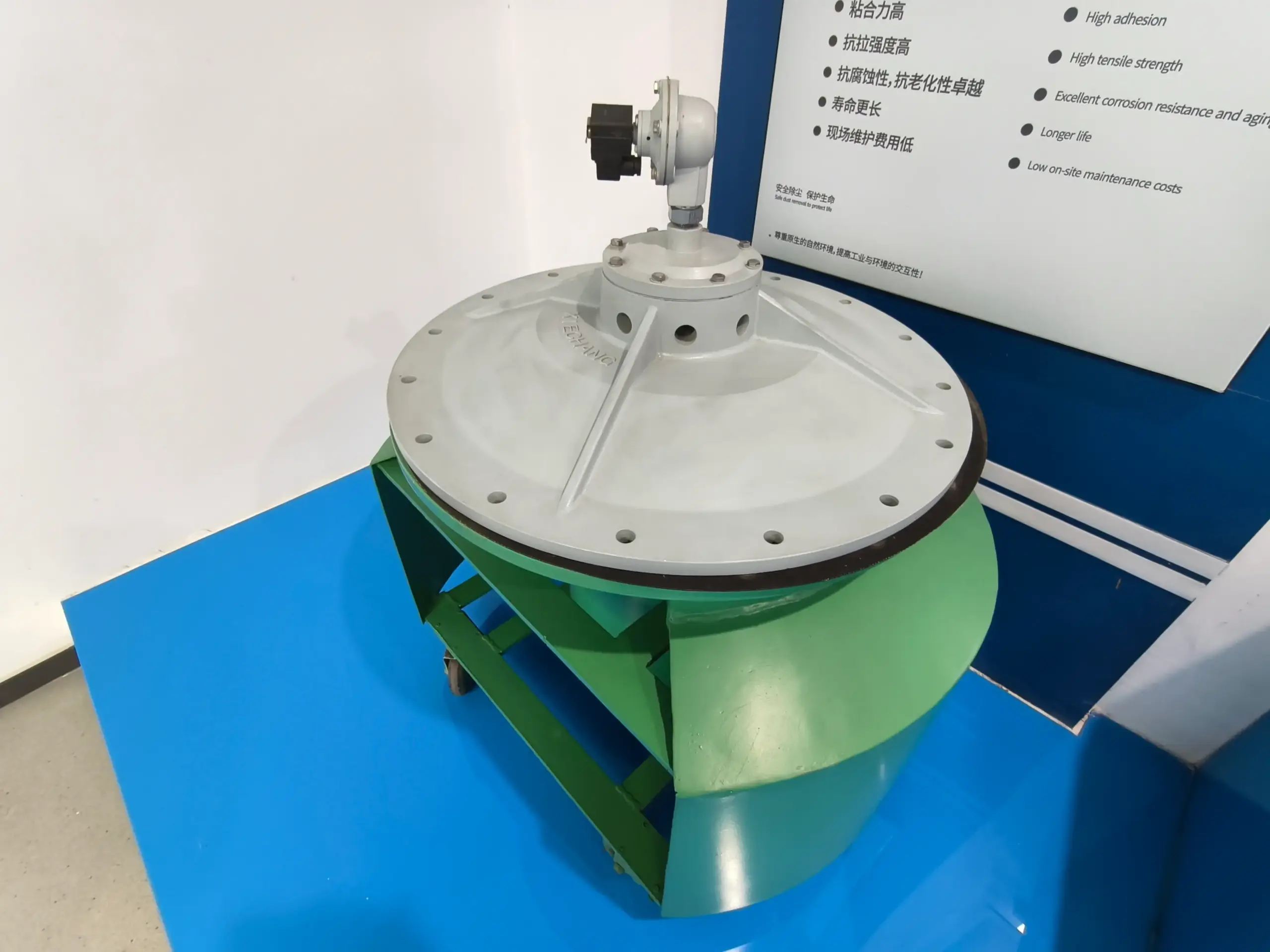

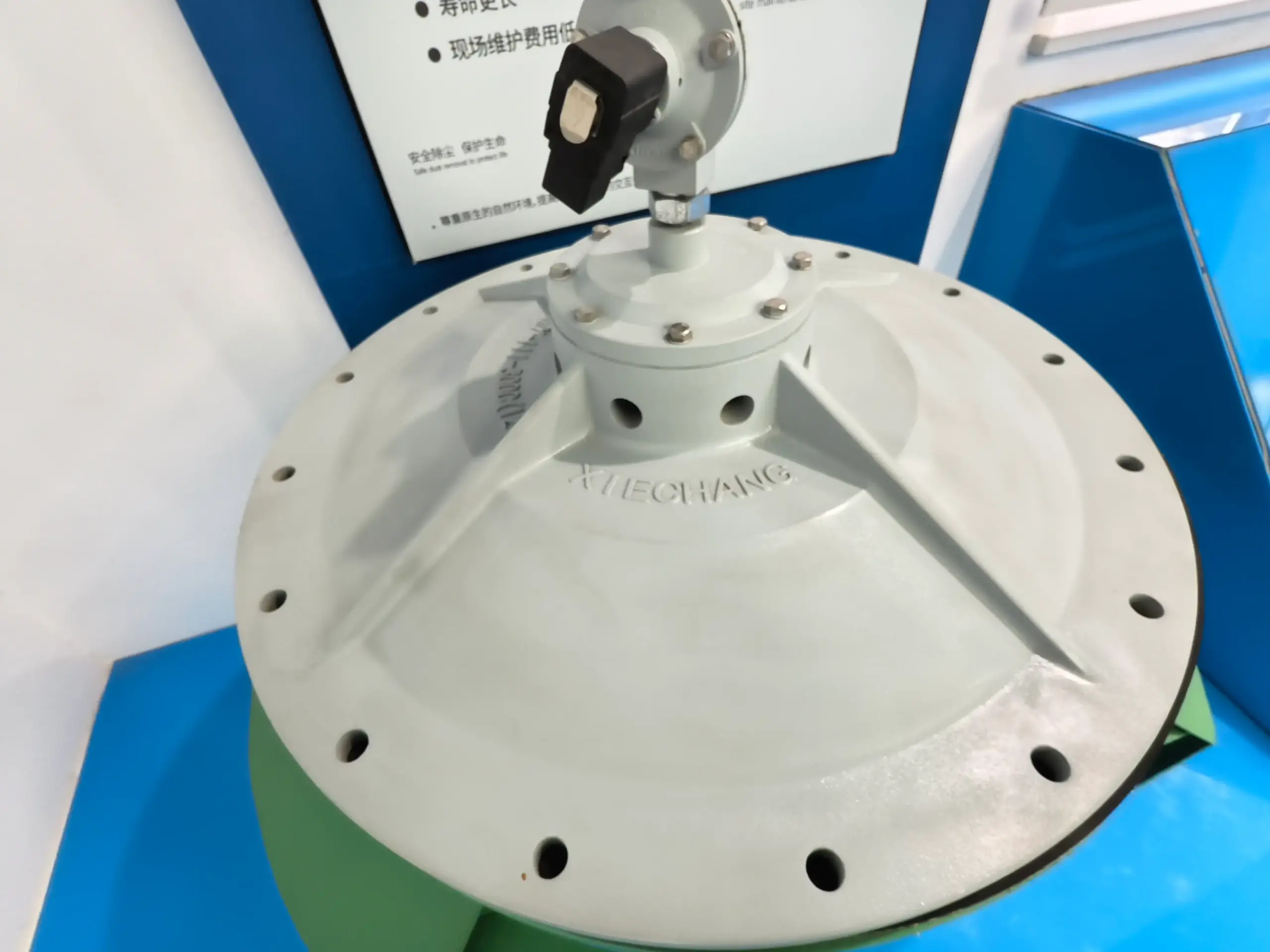

Integrated Tank Design: The valve is manufactured as an integrated unit with the compressed air tank, making the installation and maintenance of these heavy-duty components exceptionally convenient.

3. Working Principle

The pulse valve operates through a high-precision pressure balance system involving an solenoid post, a diaphragm, and the valve body:

-

Standby: The pressure in the rear diaphragm chamber exceeds that of the front chamber, keeping the valve firmly closed.

-

Activation: An electrical signal engages the solenoid, opening the unloading hole and rapidly venting the rear chamber pressure.

-

Blowing: The front chamber pressure lifts the diaphragm, opening the main channel for a high-volume air burst.

-

Reset: When the signal stops, the spring resets the solenoid to close the unloading hole; pressure then equalizes via the damping hole to reseal the valve.

4. Technical standard:

| Technical category | Related parameters |

| Working pressure | 0.05~0.1MPa |

| Working medium | Clean air |

| Voltage | DC24V(AC220V/50Hz) |

| Current | 1.25A(0.5A) |

| Protection level | IP65 |

| Working environment | Temperature: -25 ℃~100 ℃ (normal), 120 ℃ (transient)

The relative humidity of the air does not exceed 85% |

| Diaphragm service life | About 1million times of blowing |

5. Product parameters:

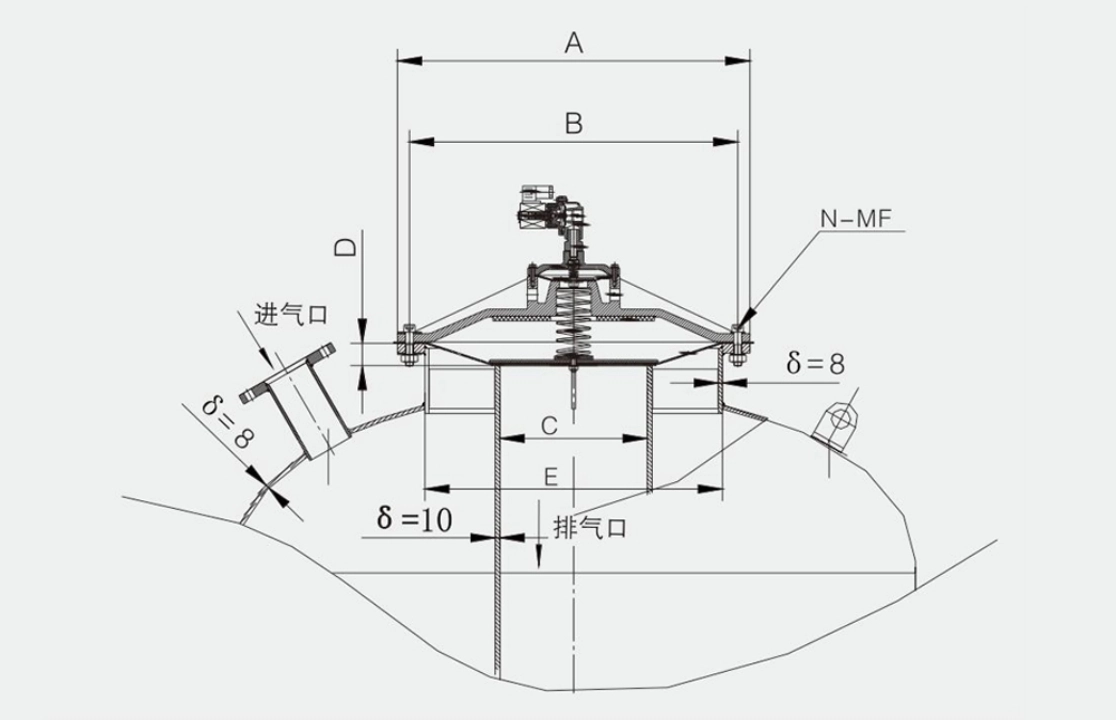

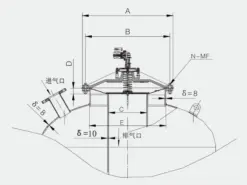

| Model No. | Standard air tank volume | Size | Installation dimensions | Installation dimensions | ||||||

| British(inch) | Metric(mm) | A | B | C | D | E | N | MF | ||

| DMY-III-200C | 1.3~1.8m³ | 8″ | DN200 | φ490 | φ457 | φ200 | 35±0.1 | φ430 | 12 | M10 |

| DMY-III-250C | 1.3~2.2m³ | 10″ | DN250 | φ600 | φ560 | φ255 | 40±0.1 | φ514 | 16 | M12 |

| DMY-III-300C | 1.5~2.5m³ | 12″ | DN300 | φ730 | φ680 | φ305 | 46±0.1 | φ616 | 16 | M16 |

| DMY-III-350C | 1.5~2.8m³ | 14″ | DN350 | φ842 | φ780 | φ336 | 57±0.1 | φ716 | 20 | M20 |

| DMY-III-400C | 1.8~3.5m³ | 16″ | DN400 | φ940 | φ870 | φ406 | 50±0.1 | φ806 | 24 | M24 |